When you think of Mountain Productions, it’s no surprise that staging and music events are the first thoughts that come to mind. Behind the stages, however, has been our transition from solely a staging company to that of an integration company, providing vendor services in Engineering, Fabrication, Installation and Rigging Sales. This integration focus allows us to provide each service as a stand-alone offering, where anyone can approach us as a trusted third-party vendor to assist in entertainment and industrial installations. Our recent installation at Longwood University, where our experienced team engineered, fabricated and installed rigging attachment points for the speakers and scoreboard, is just one example of our crew’s capabilities and expertise in custom-creating solutions that are tailored to each of our client’s requirements. With each project we undertake, there is always a unique set of challenges and considerations that must be considered, and our time at Longwood University was no different. Below, we take you through our full journey at Longwood and highlight the rigging, design, safety compliance and project management considerations presented at each stage of the project.

Planning & Initial Phases

Initial planning phases for Longwood began back in the fall of 2022 when our crew made the trip to Farmville, Virginia to mobilize the site and conduct site orientation. Gaining access to the site ahead of the installation was a big advantage for our crew. By knowing the lay of the land, many unforeseen situations can be rectified and plans for deliveries and moving goods into or out of the building can be established.

Site access also plays a substantial role for our engineers. They often see differences between the drawings and physical structure, allowing them to make changes to hardware, rigging or even fabrications before the physical installation is due to take place. Having the opportunity to make these changes ahead of time can save hours, days or even weeks and keep the project steady and on schedule.

Rigging Attachment Design, Engineering & Fabrication

Once site orientation was completed, our engineers began designing the rigging components required for the installation. Designing rigging attachment points demands a comprehensive understanding of the project requirements and any supply chain issues that may lead to extended lead times.

With both the client and our engineers satisfied with the proposed designs, all components for the installation were fabricated. One of the key components with this project was its “finish”. It was important that our rigging and fabrications blended in with the building structure and didn’t look out of place. The scoreboard posed a unique challenge in this regard as the rigging points initially didn’t align with the roof joists. To overcome this, our team ingeniously designed a sub-structure that seamlessly transitioned between the two while still allowing for the required trim height. In cases like this, where standard solutions don’t suffice, custom components are usually required.

Installation Commencement

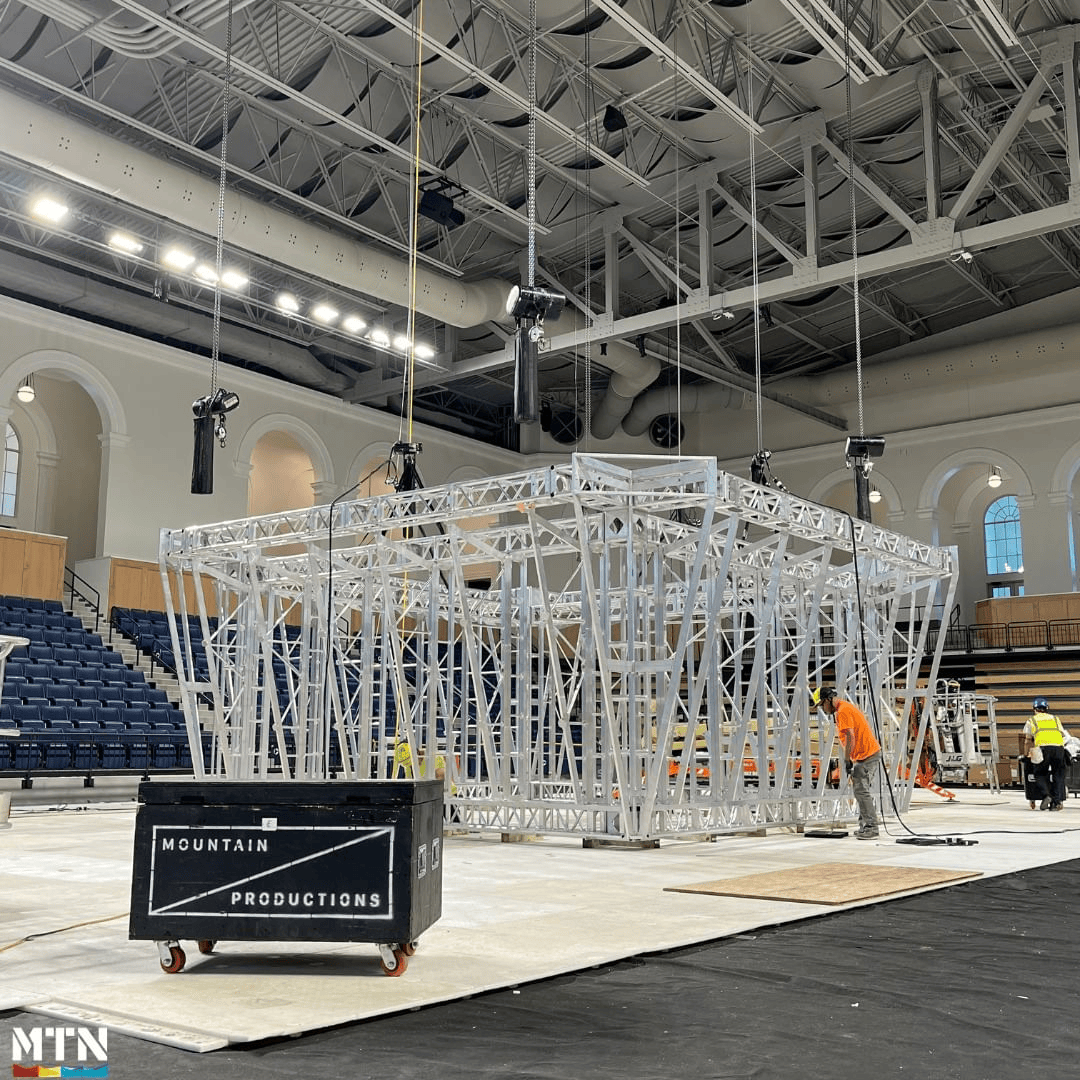

Next it was time to go on-site to begin the actual installation, carrying out the physical hanging of the custom fabricated brackets and frames, rigging accessories and the client’s audio and video components. All hardware, rigging and fabrications were mated up with the items to be installed, whether that was speakers or the frame for the center-hung scoreboard. From there, the blueprints were meticulously followed, clamps were bolted in place and the items connected using the rigging and hardware. To ensure that everything was correct, measurements and angles were then double checked.

The scoreboard once again posed issues during the installation process as it was dead hung. To overcome this challenge, our install crew used temporary hoists to move the 14,000 lbs unit into place and then transitioned it from those hoists to the permanent rigging that was attached to the ceiling. Moving roughly a 25’ square that is 10’ tall required every move to be extremely slow and methodical to avoid any damage.

Excellence in Every Detail

The Longwood University installation showcased our integration team’s expertise, adaptability, and unwavering commitment to excellence. With our ability to engineer custom solutions, maintain rigorous safety standards, and adhere to tight timelines, this new facet of our business allows us to provide bespoke client solutions no matter the size of the project. At MTN, we’re more than just a staging company, we’re a trusted third-party vendor committed to delivering exceptional results that surpass our clients’ expectations.

To discover how we can elevate your next project to new heights, contact our team today by emailing info@mountainproductions.com or calling (570) 826-5566. Check out our website at: https://www.mountainproductions.com/