OSHA released the top ten most common workplace safety violations for 2015 in October, and you’ll most likely not be surprised by what you read. These top ten violations have been identical for the past 5 years, and are recurring issues across the industry for many years now. They are also areas that are very common to our industry, and situations that ourselves and our colleagues deal with every day. Here’s the list, along with some tips on how to avoid a hefty OSHA fine in the future:

-

Fall Prevention (6,721 citations)

Our crews are frequently working at height, and are mandated to use proper personal fall protection and fall arrest systems where necessary. Falls are the leading cause of fatalities in the construction industry.

Avoid this fine and more importantly, any accidents, by equipping yourself with a proper harness, lanyard, and hard hat/helmet. These essential fall protection items will save your life. Training for proper usage is paramount, as these products only work when used correctly. Combine these with reliable fall arrest systems (ex. DBI-SALA’s Sayfline Horizontal Lifeline) for a complete fall protection solution.

-

Hazard Communications (5,192 citations)

Keep your facility properly labeled and marked. This includes signs, labels, SDS sheets and employee training. This standard was updated with the UN Globally Harmonized System of Classification & Labelling of Chemicals back in 2012. Although they may seem extraneous, proper signage around your workplace (especially around chemicals and machinery) can save lives. A simple Google search of “hazard communication” will return helpful resources, documentation, and the signage & training necessary for compliance.

-

Scaffolding (4,295 citations)

Almost every one of our projects involves scaffolding. We’ve designed whole systems around it, but have also spent much time finding the strongest and safest scaffolding products available. Our scaffolding is carefully engineered and reviewed by our in-house engineering team. All of this combined with competent training allows us to state confidently that our scaffold is at code and built properly. Invest in the same research and training to make sure your scaffolding is compliant.

-

Respiratory Protection (3,305 citations)

Workers must be protected from unseen airborne harm via compliant respirators. We make sure that our staff is thoroughly evaluated to see if they require respiratory protection, and then buy various levels of respirators to make sure any and all of our shops are protected.

-

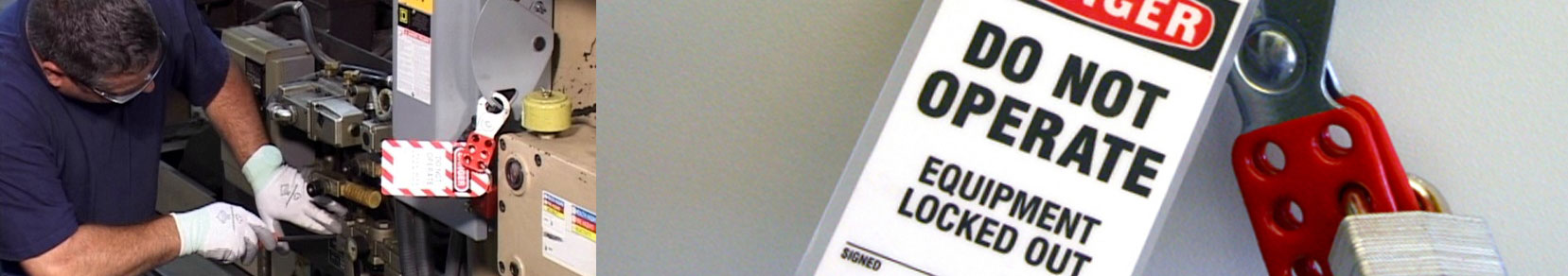

Lockout/Tagout (3,002 citations)

With all of the machinery and equipment that is necessary to get our jobs done, it’s evident that things will break. When this happens, it is imperative that each piece of compromised equipment is properly locked out from further use in order to avoid any misuse of damaged goods. Prevent any unexpected injuries by purchasing a lockout/tagout system to use throughout your entire shop. It’s important to train your employees at least yearly on the lockout/tagout system.

-

Powered Industrial Trucks (2,760 citations)

We’re in the business of heavy lifting, and the industrial vehicles that we use must be maintained and compliant. We keep an updated forklift maintenance sheet that is filled out by our operators. Additionally, all of our other industrial vehicles are serviced regularly by our mechanic shop. Invest the time and resources to keep your fleet running properly—you don’t want a forklift to fail.

-

Ladders (2,489 citations)

Another necessity in our industry, ladders can be a big contributor to accidents and falls. Be aware of your ladder inventory, and when one is up for service or replacement, make use of your lockout/tagout kit to clearly mark the damaged ladder. An inventory checklist is another way to confidently keep track of your ladders.

-

Electrical Wiring Methods (2,404 citations)

This standard covers grounding, installation and other practices to ensure properly wire equipment. Make sure your machinery and electrical equipment is installed by a professional, and inspected to be sure everything is in working order. Arc flash training is also recommended to ensure worker safety. Make sure access points (breaker boxes, etc.) are marked and are free and clear of debris. If a machine is in need of maintenance, use your lockout/tagout system.

-

Machine Guarding (2,295 citations)

Review all of your inventory to see which pieces of machinery in your shop need proper guarding. If a system is not in place already, do the homework necessary to safeguard the operator from any nip points, debris, sparks, etc. Regardless of the solution, it is necessary and worth the investment to keep your crew safe.

-

Electrical General Requirements (1,973 citations)

This last violation can be related to #8—always make sure your electrical equipment is regulated and installed by professionals. An electrical failure can cause severe damage, and can even lead to an additional fall if experienced at height.

There’s no excuse to avoiding OSHA regulations at work. While OSHA monetary fines are a big factor that companies want to stay away from, they shouldn’t be the driving factor for staying safe on the job. Your families are. OSHA’s set of rules have been set into place in order for you to get home safely, every day, no matter what. Make the investment to comply up front, and you’ll be rewarded with satisfied workers and a safe workplace environment that you’d be happy to have OSHA representatives walk through.

This article was written using information from http://www.allonehealth.com/news-media/2015/11/05/top-ten-osha-violations-in-2015.aspx